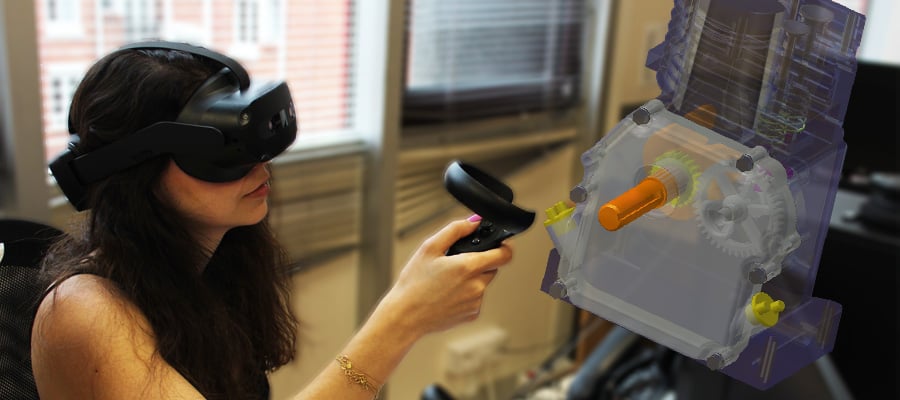

Looking for a way to enhance your design/engineering/manufacturing process when working with CATIA V5 models? A great solution lies in 1:1 scale visualization with Virtual Reality (VR) and Augmented Reality (AR). These immersive technologies close the gap between the 2D screen of your CAD application and the physical world, and allow industries to exploit the power of digital prototyping as a competitive advantage.

And it gets even better when no 3D data is translated from your native CATIA V5 application to the VR environment.

If you are new to VR, you may be wondering: why should I visualize a Catia model in VR? How can I run a 1:1 design review session? Why should I avoid converting my CAD data? In this blog post, we will walk you through each step of the way, as well as offer you a deep dive on the advantages of working with CATIA models in VR.

Why should you complement Catia V5 with a VR software?

CATIA (Computer Aided Three-Dimensional Interactive Application) is a 3D modelling software edited by Dassault. It is the primary 3D design system used across various industries for parametric modeling and non-parametric modelling, designing products, and simulating manufacturing processes.

Seamless data integration from design-to-market has become a major concern for Industries. Data is at the core of modern product development, but it is too often trapped on 2D pages and screens. Thus, it can be difficult to properly assess what the final product will look like.

For example, imagine that you are following your GPS instructions while driving your car:

- The GPS announces a direction

- Your eyes leave the road to gather more information

- You need to retain information and translate it into the physical world

- Finally, you act on the first instruction – while keeping control of the car the whole time

The entire cognitive journey can be very taxing. This is why car manufacturers like to use Head-Up-Displays (HUDs) and display information on the windshield to overlay the relevant data in context. The easier the data can be visualized and interacted with, the lower the cognitive impact.

Consider now the cognitive impact of viewing CATIA V5 models scaled down to fit the 2D screen of your computer. Trying to understand the impacts of a change of design is very taxing. Visualizing your CAD models in VR enables you to close this gap between the virtual and the physical environment – and better your overall design-to-market process.

4 advantages of visualizing a CATIA V5 model in virtual reality

CATIA V5 only allows you to visualize your designs through a computer screen. But it is not the only advantage of taking a CATIA V5 model into a virtual reality environment:

- Enhanced design reviews in XR: Virtual reality and augmented reality technology provide an immersive environment that allows engineers and designers to fully experience their CATIA model in a more realistic way. For example, it helps them better understand their mechanical design and identify potential flaws, before having to make the physical prototype.

- Improved collaboration: XR can enable real-time collaboration between users and viewers – regardless of their location. They only need a good Wi-Fi connection. It can help teams work more efficiently – especially for big organizations with one headquarters and various production units across the globe.

- Better ergonomic analysis: XR allows engineers to simulate how a product would function in real life, enabling them to optimize the design for better ergonomics and usability. Whether you are designing a workstation for operators, or the cockpit of a vehicle, XR is ideal for ergonomic and reachability studies.

- Cost savings: Visualizing 3D models in AR or VR will reduce the need for physical prototyping, thus saving costs and resources. Additionally, by identifying risks and errors early in the design-to-market process, XR avoids costly rework. This can result in significant cost savings for manufacturers.

What is the Catia V5 to VR workflow with TechViz?

What you will need to visualize CATIA V5 models in VR

Ready to take your design and visualization game to the next level? If so, you will need:

- A CATIA V5 license

- An XR device to visualize the 3D model:

- An all-in-one HMD like the Meta Quest 2

- OR a tethered headset like the Vive Focus 3

- OR a pair of AR glasses like the Lenovo ThinkReality A3

- OR an immersive room like a 4-sided VR CAVE

- OR a powerwall or a LED wall

- A VR-Ready PC

- TechViz software

If you do not have a TechViz license, you can start a 15-day trial here.

3-steps workflow for CATIA to VR

TechViz instantaneously displays CATIA V5 models in 1:1 scale on any XR system – even with multiple AR/VR devices. Our intuitive software acts as a driver to your XR system, enables you to be fully immersed in your 3D CAD data and interact with the native application.

Here is how to display CATIA models in VR in one click:

- Start CATIA V5 and load your 3D file

- Open TechViz and select CATIA

- Instantly display your CATIA model in virtual reality

TechViz can display very large CAD models (up to 1 billion triangles), while keeping a high frame rate. Whether you are working on small-scale products or large industrial equipments, we have got you covered.

One of our software major priorities is to be integrated seamlessly into your processes. Therefore, your CATIA model is displayed in VR without data conversion. There is no need to prepare or optimize your files beforehand. It also means the changes in VR are happening in your native application in real-time.

Experience Catia V5 designs like never before with TechViz

CATIA V5 is one of the most used CAD software by engineers – because it is very versatile. Of course, there are a lot of functionalities available in the soft, and licenses are generally broken down to include the required features. Depending on your license, different CAD tools and/or workbenches will be available.

Here is how TechViz can take your 3D design software a step further with XR.

1. Visualize rich 3D models in real-time with no data conversion

Imagine that you need to create parts for specific products like engines – and sometimes you need to make bespoke adaptations. You will need accurate measurements before launching production. CATIA can help you centralize all the information, but it will be difficult to visualize if the wanted design fits your engineering requirements. With TechViz, you can avoid endless back-and-forth between teams by immersing all the stakeholders in the same virtual space, interacting in real-time with your CATIA model at scale 1:1.

You do not need additional resources for data conversion, and the potential risk of errors or data loss. This way, you can maintain the accuracy and consistency of your original 3D objects, and ensure the quality of your virtual prototype.

2. Simulate real-like process in XR from any CAD/CAM data

Sometimes, flat rendering is not enough to understand – or explain – complex sets of data. Being completely immersed in them helps to analyze how things connect and interact. Let’s say you’ve built an accurate 3D model of your production facility – with all the equipment and various parameters. A CATIA model can help you visualize and optimize your product development process, but it will never be as accurate as being physically in your own model and being able to visualize complex 3D data.

3. Merge 3D scenes from different applications into a single digital prototype

If you are working with contractors and manufacturers that do not use the same CAD program you do, then it can quickly become a problem. Instead of facing tedious CAD file conversion, you can use TechViz Fusion, a feature that enables you to merge data from different application into a unified virtual scene.

.jpeg?width=900&height=400&name=FHK2LQ4IOVEMTFHAH7B7OTXGZA-jfif-1-1%20(1).jpeg)

4. Move parts and detect collisions in 3D models

In a 3D assembly model, components of a product are brought together to define a large-scale and complex model. TechViz can handle models up to 1 billion triangles, simulate clash of parts and 3D collisions in virtual reality. This feature facilitates collaboration between engineers, designers, analysts, and manufacturers to ensure their assembly works together.

XR technology is rapidly transforming the way professionals work and stay competitive in today's fast-paced world. With the power to seamlessly integrate with native software like CATIA V5, there is no reason why you should not take advantage of the many benefits VR has to offer.

So, take the leap and try out TechViz's 15-day trial today to experience the full potential of VR technology. See for yourself why XR is the next step for professionals looking to succeed in the future.

Back to Blog

Back to Blog