Today, we are witnessing the digitization of manufacturing, a transformation so complete it compels the sector to find new business models and innovative solutions to increase productivity, profitability and safety of their employees. This transformation is called Industry 4.0. and deals with the huge amount of data that we are generating every day, and how to use it. One of the most effective ways to visualize and exploit this information is through Augmented and Virtual Reality (AR/VR). This enables new opportunities, especially for manufacturing industries.

However, only 28% of companies implemented AR/VR solutions in their process in 2018 (according to PwC) compared to more specialized tools that “digital champions” had been using for years. This article deals with what Industry 4.0 means for the manufacturing industry, and the benefits of adopting VR tools in your process.

TABLE OF CONTENT:

- Why companies need to be digitally mature to adopt VR and embrace industry 4.0?

- Why is the adoption of VR tools important for the development towards industry 4.0?

- 4 benefits your business can get from using VR for manufacturing

Why companies need to be digitally mature to adopt VR and embrace industry 4.0

There has been a lot of talk about companies going through digital transformation. However, being digitally mature isn’t a static end point. Companies can’t just include Virtual Reality in their process (or just in their design phase), and expect that the adoption of the new techs, and the new ways of working will help with their productivity with a snap of their fingers. But as technology keeps on evolving, adopting AR/VR tools in your industrial process becomes a sign of digital maturity.

Industry 4.0 depends on the evolution of technology, but it also implies a necessary thought and planning process. Being digitally mature means taking advantage of the technological developments prompted by the changes in your target market, by cultivating the skills and tools to understand and respond to market changes.

For instance, let’s imagine two similar small business, let’s call them A and B who realized they should create a website that allowed for online orders to remain competitive. Their websites are very basic, with a rudimentary design. If you ask them if they find themselves digitally mature, both will answer ‘yes’, however they have very ideas about what it means. A thinks it simply means they need a website to bring new business. B understands why having a website was necessary, and what the step further might be.

A few years later, the market has changed. People want customized product and being able to choose the delivery date. B understands this because they will try to follow the market changes by continuously upgrading their website, and getting acquainted with the new needs of customers. In the end, A’s business suffered, because he thought just having the website made him ‘digitally mature’.

A digitally mature company will always research into their market and the tools at their disposal, such as VR technologies. Adopting new process and tools also means understanding your competitors and how they used the tools to better their business (depending on their own challenges and opportunities for growth). This is probably why adopting VR technologies is a sign your business is evolving towards Industry 4.0.

Why is the adoption of VR tools important for the development towards industry 4.0?

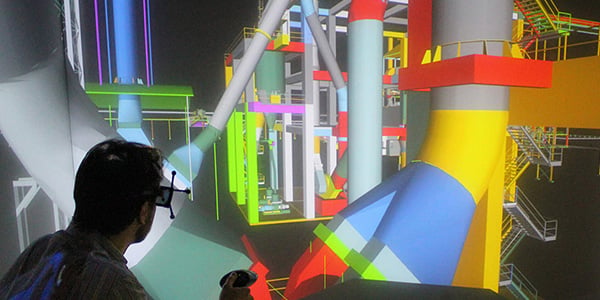

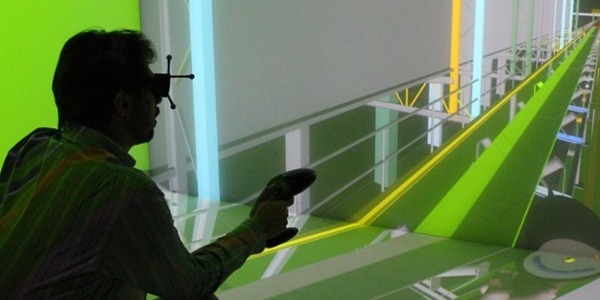

Virtual Reality (VR) is a technology which enables to generate a virtual environment, either to simulate the real world (for example with CAD models in virtual reality), or enabling to visualize phenomena otherwise invisible to the human eye (for example simulating assembly process). TechViz VR collaboration software has already helped business with different Use Case of using VR for manufacturing line.

The factory of the future should be able to adapt to the new market trends, as product life cycle become shorter and shorter, while consumers demand personalized high-quality products. As a consequence, manufacturing companies are looking to optimize their production process to:

- Cut maintenance and repair costs

- Achieve higher machine availability

- Reduce downtime manufacturing

Most of today’s “digital champions” have identified the types of technologies they need in their process thanks to the added value they can provide to their customers. These technologies mostly improve the company’s performances, or help them extract and transmit the information. These new business process rely on software with the highest data security to record, evaluate and optimize their product in real-time, at each manufacturing stage.

For manufacturing companies, most of today’s VR applications can be a game-changer for maintenance, service and quality assurance. Besides, as businesses are expected to react quickly to market changes to keep their competitive edge, VR training alerts your teams about the changes expected in the operating procedures.

4 benefits your business can get from using VR for manufacturing

1. VR reduces your time-to-market

Sometimes, your business model relies on process that struggle to keep up with the market trends. The digitization of the supply chain pushed by Industry 4.0 by the usage of Virtual Reality enables to shorten the time needed to design, test and control the quality of your products before launching them.

2. VR reduces the risk of on-site accidents

Manufacturers who have used Industry 4.0 technology in their process have reduced the chances of accident, by taking the safety training to the next level. By using a virtual reproduction of your production site and/or simulating your process, you can train your teams more efficiently. Virtual Reality raises the operationality of your employee and minimizes the risks.

3. VR improves the quality of your products

Virtual Reality can intervene at every step of your design-to-market process, by making the entire process more immersive and allowing an easier collaboration, even with remote workers! You will detect errors earlier, thus avoiding product reworks and raising client trust.

4. VR helps avoiding machine downtime or process disruptions

Virtual Reality and Industry 4.0. allow you more than being able to check the quality of your by viewing it on different angles or display it to stakeholders. By actually simulating how your specific industry works, not only will you be able to find the flaws in your product, but also in your production process, and therefore be able to improve it.

TechViz VR software is a versatile and scalable solution adapted to the manufacturing industry. To fit with your usage scenario, we developed several features with industry leaders. Our software is compatible with any VR system you implement and is scalable to unlimited display channels. Want to ask about your specific use of VR ?

Back to Blog

Back to Blog