The automotive industry is a fast-paced sector which continuously adopts technologies that powers their digital transformation. Virtual Reality (VR) is one of the most fitting technology to provide the automotive sector with new methods and tools to design better vehicles, test different configurations, check driving ergonomics, refine manufacturing processes, etc.

A lot of departments and experts are involved to conceive a brand-new car: designers, engineers, manufacturers, workers on the assembly line, marketers, sellers... The complexity of this process makes the design-to-market time around 2 or 3 years for each vehicle, a very long time in a moving industry. This article is an overview of the uses of VR in the automotive industry:

- How VR helps with the automotive design process

- How VR plays a key role in the automotive production process

- How VR enables better car ergonomics

- How VR became a game-changer for automotive training programs

The use cases of virtual reality in automotive industry featured in this article come companies relying on TechViz VR software. If you’re interested in getting more information, don’t hesitate to contact our sales teams. If you're more interested in a global overview of the use cases of VR, check-out our complete guide of VR for business.

How VR helps with the automotive design process

Automobile (and other vehicle) design has always been a long and tedious process. This stage of the product conception involves shaping the outside and inside of the vehicle. Quite often, design purposes will not be compatible with engineering requirements. For example, a form can be aesthetically pleasing, but not very aerodynamic. Thus, making a car which corresponds to what the designers and the engineers want takes time, resources and compromises.

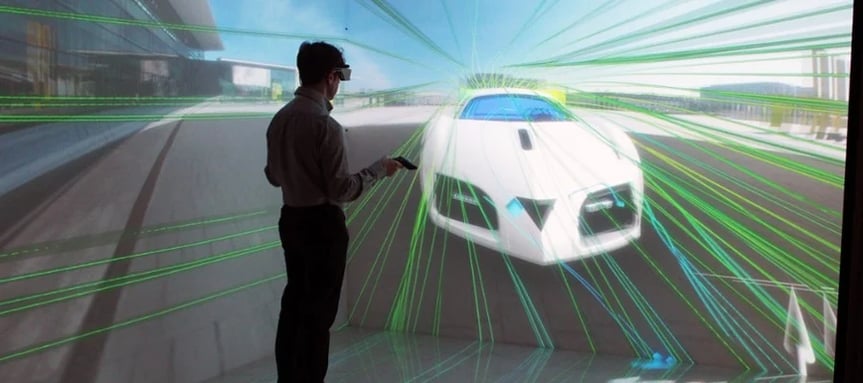

With 3D modelling and VR visualization software like TechViz, designers and engineers can now use their CAD application to conceive the vehicle directly in 3D. It enables better visualization of the vehicle, and the ability to see and interact in real-time with the model at 1:1 scale with a 360° view. Generating different configurations becomes easier (even more when generative design matures enough). Also, it can also help to check the later details for interior design such as the colors of the materials, their texture, and so on.

For example, one car manufacturer has equipped its engineers with HTC Vive, so they can work on the first ideas and choices with the HMDs. Then the results are presented in a CAVE that can be booked only when needed (it’s more cost-effective). They chose TechViz because the software is compatible with all VR systems: AR/VR headsets, PowerWalls and immersive rooms.

Also, companies can also use VR collaboration to make real-time validation with design teams from different services, or located at different places. This can really improve the teamwork between designers and engineers, and help them get input from other key department like production, marketing or sales. For instance, one of our client uses TechViz VR collaboration feature to facilitate communication between several services scattered around different countries, in order to check most of the design before the final project review.

How VR plays a key role in the automotive production process

Virtual reality in automotive industry has gotten really important in manufacturing and assembly. For instance, in the validation process, a car manufacturer uses TechViz for their validation process. Operators check with a VR simulation of the assembly to time how long repetitive task takes. Thanks to TechViz, they saved 30% decision time, because they can experiment in VR straight from the CAD application.

Every second counts in the manufacturing process. Saving time is a priority for car manufacturing. However, it can be hard to see where the waste of time or resources happens in the line. This is where TechViz software and VR for manufacturing intervene for one of our clients. Being immersed in the 3D representation of the assembly line enabled them to test different configurations in real time by moving machines and containers. Visualizing their process through an HTC Vive with TechViz helped them understand and solve issues they didn’t understand with their last software.

How VR enables better car ergonomics

![]()

Using VR tools like an immersive room and a full body-tracking suit not only helps evaluating the interiors of the vehicle, but also conducting ergonomics analysis. Are the mirrors visible from the driver’s seat? Can the driver reach the different commands in the car? These questions can be solved easily with VR technologies, without wasting time or resources to produce a physical prototype.

One of our clients in the automotive industry decided to take the experience even further, with Techviz’s Fusion feature. They used a driving platform in an immersive room, and displayed a CATIA model of the cockpit, and merged it with a 3D driving scenario. This installation enabled the engineering team to sit in a VR model of a car and take it for a drive in a real-like environment. It contributed greatly in perceiving the quality of the future car models and checking the ergonomics.

Note that these ergonomics can also be applied to assembly lines. Another client in automotive used TechViz and body tracking to check their workstation ergonomics. With a combination of their PLM software, TechViz and a tesla suit, they noticed that the workers couldn’t reach the “stop the line” cord easily, which made quality control very difficult for their employees. Running several VR simulations helped them design a workstation more suited to their needs.

How VR became a game-changer for automotive training programs

![]()

When unexperimented workers start working at the assembly line, they are prone to commit mistakes. They can either put themselves at risk, or damage the equipment. So, how do you give them an idea of the physical work required on the line without endangering them or losing assets? By using VR training of course! It will allow trainees to fully experience the manufacturing process in an immersive environment, even if they are doing mistakes.

VR training in the automotive industry can take multiple aspects. You can either using a 3D model for new workers to understand how to handle, manufacture and assemble them. Maybe a fresh look on the parts can even get you tips for the design, who knows? Additionally, engineers and designers can get a look at how the worker is assembling the vehicle in VR, and spot the time-consuming steps or the difficult positions.

VR maintenance training can bring a lot to technicians with an immersive 3D environment featuring different cars. With the new tools at their disposals, they can confidently understand the different components, the steps to service the cars they are working on and confidently diagnose and maintain them.

Back to Blog

Back to Blog